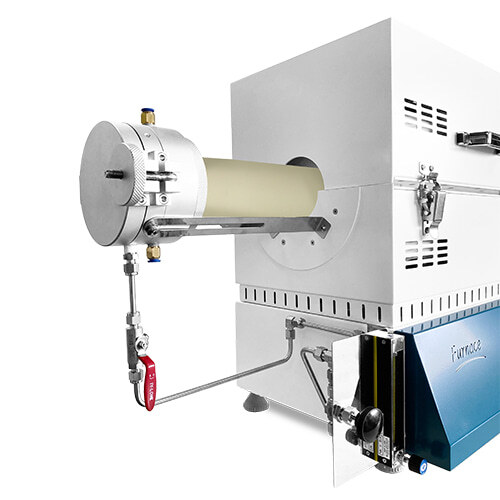

1500℃ 튜브전기로 패키지(CVD,annealing) FU-PK-H2 (300mm Ø80)

|

모델

|

FU-PK-H2

|

|

상품요약정보

|

Chemical Vapor Deposition (CVD, 화학기상증착) 공정용 전기로, annealing(소둔)용 전기로, Gas Flow package+이동형Frame + chiller + 진공펌프로 완변한 구성

|

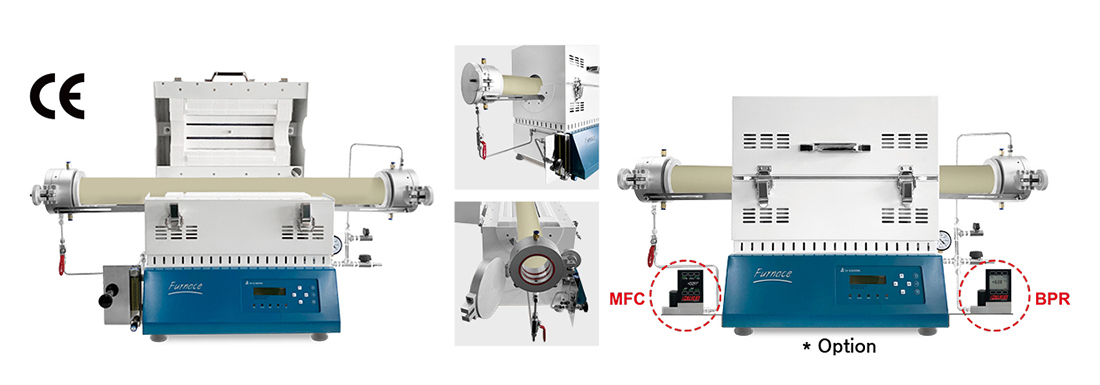

Tube Furnace Package

1500℃ Furnace FU-PK-H2 (300mm Ø80)

CVD(화학기상증착) 공정및 annealing(소둔)용 전기로 Full Package

|

Package Model

|

FU-PK-H2

|

|

Furnace Model

|

SH-FU-80TH-WG

|

|

Chiller

|

SH-WB-5CDR(-15)

|

|

Vacuum Pump

|

SH-V10

|

|

Oil Mist Trap

|

VOT-1020

|

|

Table

|

Moving Frame

|

|

Dimension

|

1265x725x1515mm

49.80x28.54x59.64''

|

|

Cat.NO

|

FUPKH2300

|

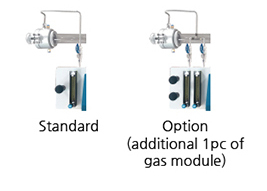

Gas Flow Package

1500℃ Furnace SH-FU-80TH (300mm Ø80)

|

Model

|

SH-FU-80TH-WG

|

|

|

Furnace

|

SH-FU-80TH

|

|

|

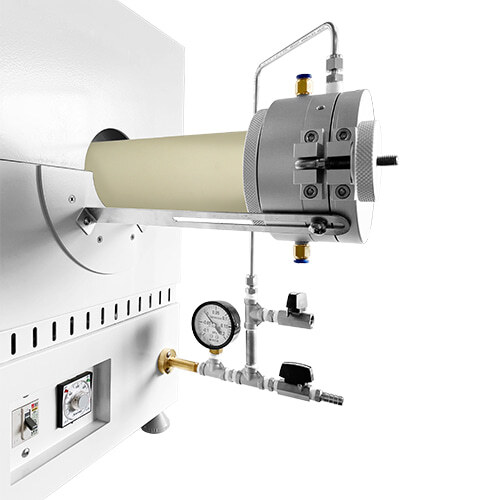

Components

|

Gas Flowmeter 1EA

|

|

|

Stainless Steel Pipe & Connector

|

||

|

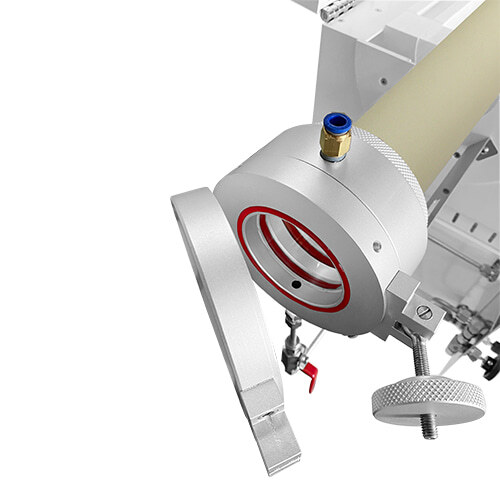

Gas Sealing Mask

|

||

|

Alumina Tube (Length 1000 mm)

|

||

|

Cat. No.

|

230 V

|

FU80THWG230

|

• Safety Device

- -Automatic reset function incoming power cut

- -Buzzer on when set time arrived

- -Over temperature alarm

• Option

- -Gas inlet module 추가

- -가스 연결 서비스

- -MFC, BPR

- -Safty Cover 튜브 안전 덮개

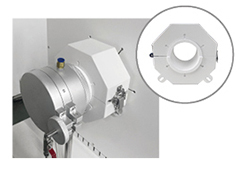

1500°C Tube Furnace

|

Model

|

SH-FU-80TH

|

|

Max Temp

|

1500℃ (2732℉)

|

|

Temp Controller

|

Programmable Controller(FC-1000)

|

|

Sensor

|

R type

|

|

Applicable Tube Diameter

|

80 Φ

|

|

Heater Capa

|

6 KW

|

|

Dimension Hot Zone

|

Length 300 mm

|

|

Dimension External

(W×D×H )

|

682x517x610mm

26.85x20.35x24.02''

|

|

Weight

|

72 Kg

|

|

Heater Element

|

SIC

|

|

Insulation

|

Ceramic Board & Wool

|

|

Electrical Requirements

230V ,50/60Hz, 1Φ

|

26 A

|

|

Cat. No. 50Hz(60Hz)

|

FU80TH230

|

콤팩트 칠러

3 in 1 Compact Chiller

|

제품명

|

콤팩트 칠러 3 in 1 Compact Chiller

|

||

|

Model

|

SH-WB-5CDR(-15)

|

||

|

Temp Controller

|

Microprocessor Digital Controller

|

||

|

Temp Range

|

-15℃ to ambient (based on ambient 25℃ / No load condition)

|

||

|

Cooling Capacity

|

Holding temp.

|

Cooling Power

|

|

|

10℃

|

980W

|

||

|

0℃

|

650W

|

||

|

-10℃

|

330W

|

||

|

Recirculating Pump

|

Max Flow

|

8L/min. (tested with clean water at 20℃)

|

|

|

Max Head

|

3.5meter (tested with clean water at 20℃)

|

||

|

Water Proof Level

|

lpx4

|

||

|

Dimension Internal

(W×D×H)

|

200x200x130mm

7.87x7.87x5.12"

|

||

|

Dimension External

(W×D×H)

|

283x400x565mm

11.14x15.75x22.24“

|

||

|

Reservior Capa

|

5L

|

||

|

Material Internal

|

Stainless Steel

|

||

|

Material External

|

Steel Plate with Powder Heating Coated

|

||

|

Electrical Power

|

230V, 60Hz, 1phase

|

||

|

Net. Weight

|

26.5kg

|

||

Vacuum Pump

SH-V Series

Perfect design and performance

고성능의 SH-V series 진공펌프입니다.

실린더 구조와 혁신적인 오일순환 시스템으로 안정적이고 강한 내구성을 자랑합니다.

자동 역흡입방지 밸브(anti-sucking back valve)와 2단계 가스밸러스트 밸브기능으로 최상의 신뢰성을 확보해 줍니다.

- 2단계 조절 가능한 가스밸러스트 밸브는 응결 가능한 증기를 펌프 밖으로 배출할 수 있게 해줌

- 오일 역흡입방지 보호기능으로, 진공시스템이 오일에 오염되는 것을 막아주며,

- 펌프가 운행을 멈추었다가 다시 작동하는데 용이

- 오일 펌프 안의 오일 강제 순환 시스템과 오일 공급 구조로 안정적인 펌프 작동 가능

|

Model

|

SH-V10

|

|

Pumping Speed(50/60Hz)

|

78L/min

|

|

Ultimate total pressure gas

ballast close

|

5x10-2 Pa

( 3.7x10-4 torr )

|

|

Ultimate total pressure gas

ballast open

|

3 Pa

( 2.2x10-2 torr )

|

|

Power supply

|

220V,50/60Hz or 110V,50/60Hz

|

|

Power rating(kw)

|

0.4(1 Phase)

|

|

Inlet/Exhaust Flange

|

KF 16/25

|

|

Oil capacity(L)

|

0.6~1.0

|

|

Ambient temperature(℃)

|

5~40

|

|

Noise level(dB)

|

≤56

|

|

Weight(kg)

|

19

|

|

Recommended for

|

Vacuum Drying Ovens

(SH-VDO-08NG, SH-VDO-30NG, SH-VDO-70NG,

SH-VDO-30NS, SH-VDO-70NS)

Tube Furnace All Packages

|

• Option

- Oil Mist Trap with Filter

- VOT-1020 : V10, V20

- VOT-4080 : V40, V60

- Filter for Oil Mist Trap

- VOTF-1020 : VOT-1020

- VOTF-4080 : VOT-4080

Flow Rate Characteristic

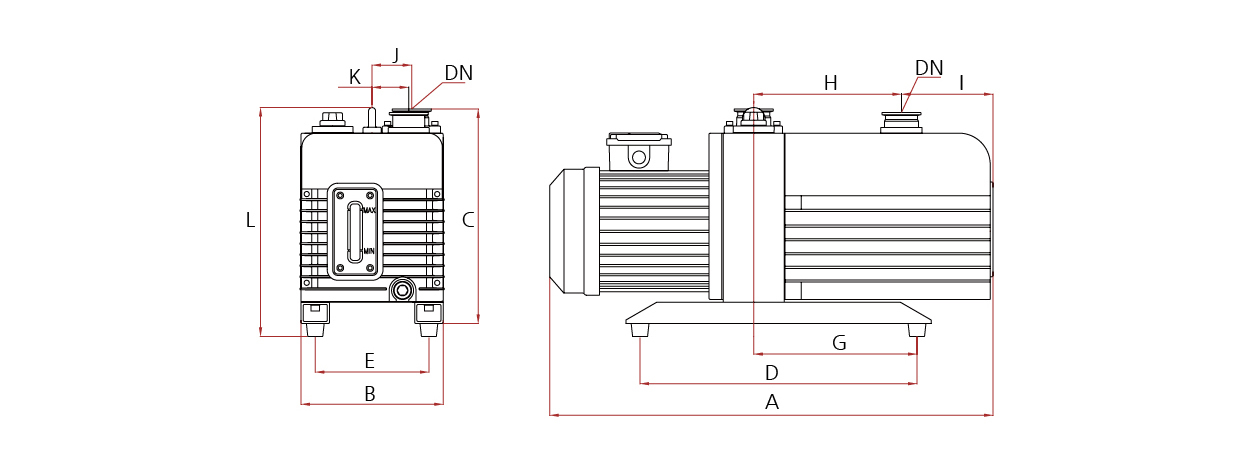

Dimension

Dimensions

|

Dimensions

|

||||||||||||

|

Model

|

A

|

B

|

C

|

D

|

E

|

G

|

H

|

I

|

J

|

K

|

L

|

DN

|

|

SH-V10

|

460

|

144

|

207

|

210

|

110

|

126

|

154

|

45

|

45

|

34

|

/

|

KF16/25

|

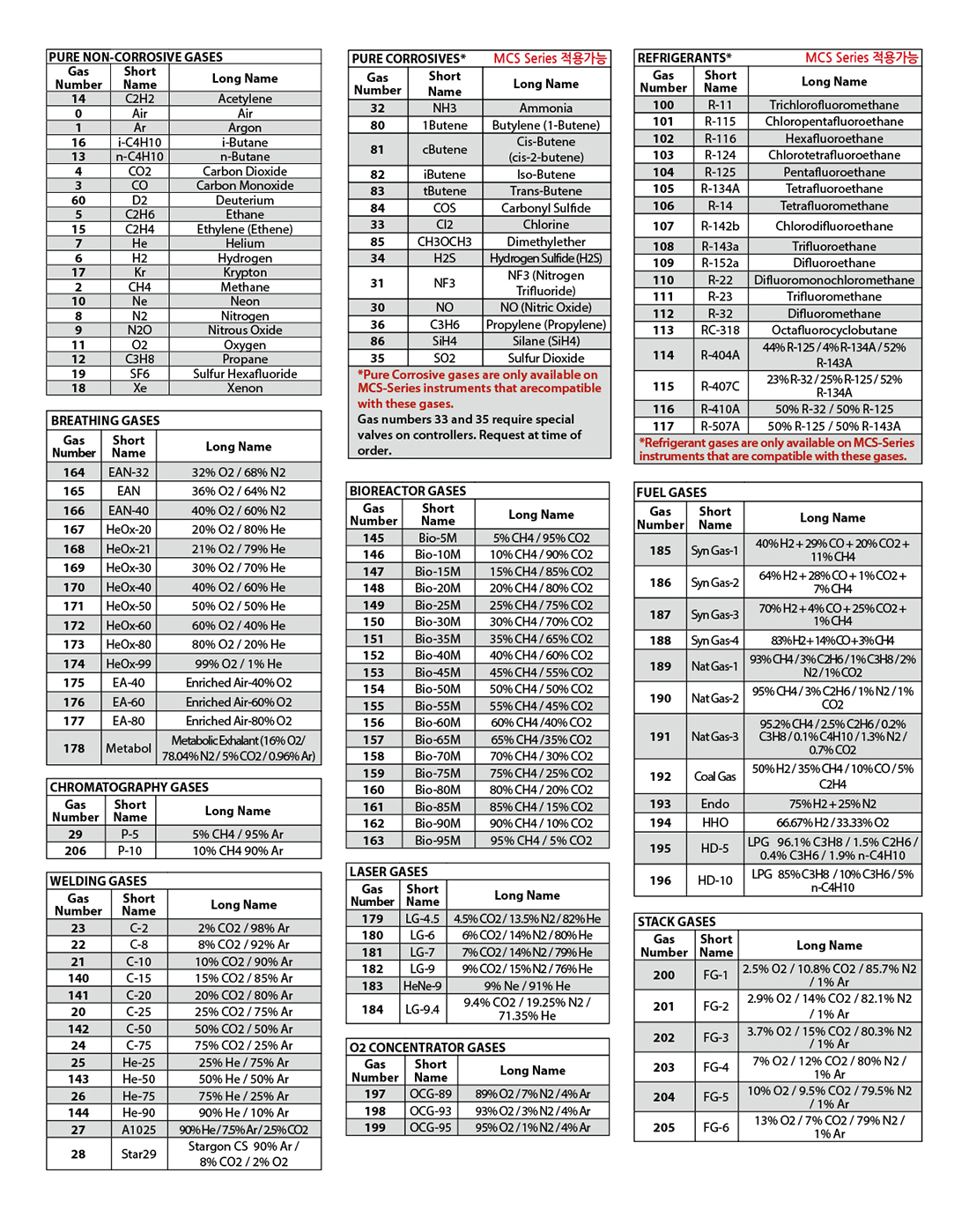

Mass Flow Controller(Multi gas selectable)

- Accessible PID valve tuning for best speed and stability.

- Custom valve orifice sizes: yields full-range stability.

- Control mass flow, vol. flow or pressure with one device.

- No warm-up: ready to control process flows in one second.

|

Model

|

MC Series

|

MCS Series

|

MCSS Series

|

MCV Series

|

|

Type

|

General

|

For Toxi Gas

|

For Toxi Gas (Cl2, SO2, HCl 포함)

|

For Vacuum

|

|

Flow Range

|

0 ~ 1 slpm / 0 ~ 5 slpm

|

|||

|

Mass Flow Accuracy at

calibration conditions

|

±0.6% of reading or ±0.1% of full scale

|

±0.8% of reading or ±0.2% of full scale

|

||

|

Operating Temperature Range

|

-10 to +60°C

|

|||

|

Temperature Accuracy

|

±0.75°C

|

|||

|

Operating Pressure full scale

|

145 PSIG

|

|||

|

Pressure Accuracy

|

Above 1 atm: ±0.5% of reading

|

|||

|

Typical Indication Response Time

|

< 10 ms

|

< 100 ms

|

||

|

Typical Warm-Up Time

|

<1 Second

|

|||

|

Monochrome LCD

|

Simultaneously displays

mass Flow, pressure and

temperature

|

Simultaneously displays mass Flow,

Volumetric Flow, pressure and temperature

|

||

|

Mechanical Dimensions

(HxWxD)

|

104.14x91.44x27.94mm / 4.1x3.6x1.1"

|

121.92x172.72x38.1mm /4.8x6.8x1.5"

|

||

|

Gas Selectable

|

98 Gas

|

128 Gas (Cl2, SO2, HCl 제외)

|

131 Gas (Cl2, SO2, HCl 포함)

|

98 Gas

|

|

Communication

|

RS-232

|

|||

Gas Select™ Preloaded Gases

Mass Flow Controller(Multi gas selectable)

- Accessible PID valve tuning for best speed and stability.

- Custom valve orifice sizes: yields full-range stability.

- Control mass flow, vol. flow or pressure with one device.

- No warm-up: ready to control process flows in one second.

|

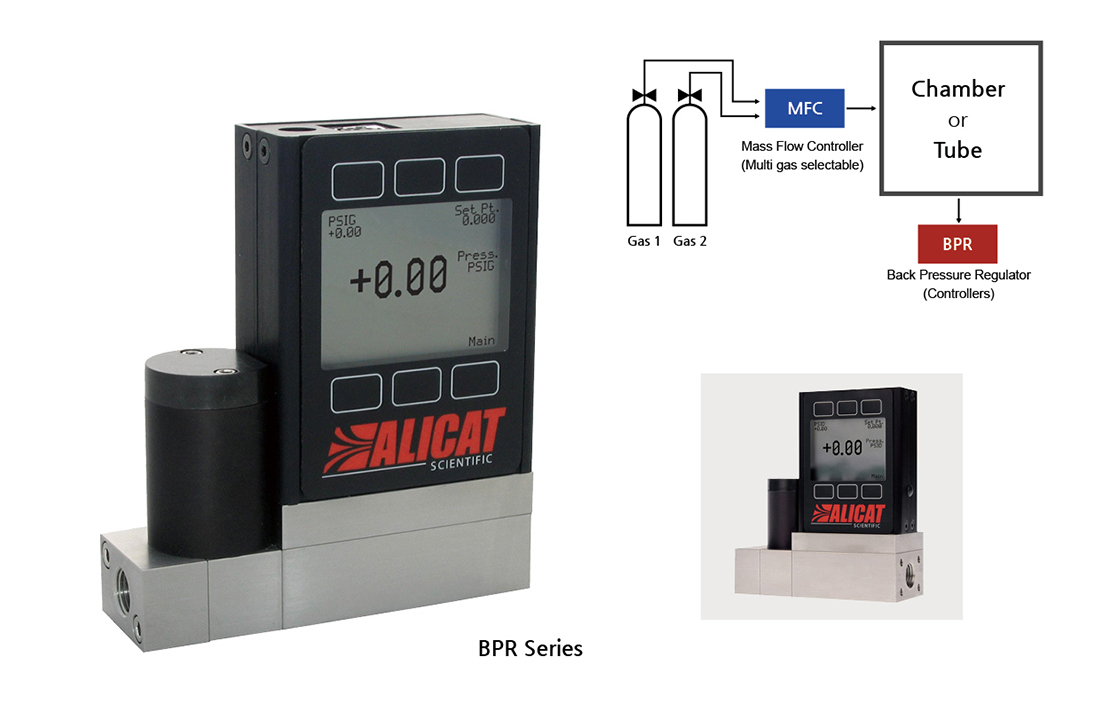

Model

|

BPR Series

|

BPRV Series

|

BPRS Series

|

BPRSS Series

|

|

Type

|

General

|

For Vacuum(음압용)

|

For Toxi Gas (CL2, HCl, SO2 제외)

|

For Toxi Gas (CL2, HCl, SO2 포함)

|

|

Pressure Range

|

1PSIG ~ 15PSIG

|

0PSIG ~ 1PSIG(0 ~ 760torr)

|

1PSIG ~ 15PSIG

|

|

|

Standard Accuracy

|

± 0.25% (≥ 1 psi)

|

|||

|

Repeatability

|

± 0.08% Full Scale

|

|||

|

Typical Response Time

|

< 100 ms

|

|||

|

Warm-up Time

|

< 1 Second

|

|||

|

Operating Temperature

|

-10 to +60℃

|

|||

|

Monochrome LCD

|

Displays Pressure

|

|||

|

Mechanical Dimensions

(HxWxD)

|

104.14x91.4x27.94mm / 4.1x3.6x1.1"

|

|||

|

Communication

|

RS-232

|

|||

적용분야

- 우주소재 및 금속재료 생산 산업분야/세라믹, 합금, 타타늄의 열처리를 수행하는 파괴시험 연구, 개발 및 생산

- Destructive testing laboratories who carry heat treatment of ceramic, alloy, titanium and etc for aerospace and metallic production industries.

- 니켈함금과 같은 금속류 분말을 소결하는 연구, 개발 및 생산

- Building companies who transforms metallic power such as nickel alloy into sintered materials by sintering.

- 고분자합성물과 그라핀을 개발하는 재료공학 연구, 개발 및 생산

- Material technology providers who develop polymer composites and graphene materials.

- 가스분위기에서 상온과 고온(1700도)의 반복산화시험을 수행하는 우주항공용 소재 연구,개발 및 생산

- Aerospace companies who perform cyclic oxidation test between high tmep to room temperature in atmosphere-controlled environment.

- 재료의 연소를 통해 성분을 분석해야 하는 의료 연구, 개발

- Medical and healthcare companies who need analysis of ashes and contents through combustion of materials.

- 진공과 가스분위기에서 소결을 해야 하는 재료 혁신 연구, 개발 및 생산

- Material innovation companies who do sintering in vacuum or in inert gases.

- 인코넬 718 튜브를 소결, 소둔, 경화하는 진공전기로가 필요한 해상용 표면 인젝션 시스템 연구, 개발및 생산

- Subsea and surface injection system companies who need vacuum furnace for softening cycles, annealing and age hardening of Inconel 718 tubes.

- 다양한 물질을 열처리시험을 통해 분석하는 연구, 개발

- Analytical research labs who perform various material testing with thermal treatment.

- 합금파우더를 소둔하는 의료용 임플란트 연구, 개발및 생산

- Medical implants manufacturers who anneal alloy powders.

- 고분자세라믹부품의 소결을 하는 대학교 재료 과학 연구,개발

- Material scientists in universities who do sintering materials such as polymer-derived ceramic parts.

- 고체산화연료전지를 가공하는 응용과학기술 분야

- Applied science engineers who process solid oxide fuel cells (SOFC).

- 연소물질이 필요한 환경 화학 연구 분양

- Environmental and chemical researchers who need combustion of materials.

- 위험물질관리, 오염토양복원, 공기오염관리 분야

- Regulatory compliance service providers in the areas of hazardous waste thermal treatment, air permitting, air pollution control, contaminated soil remediation, and hazardous waste management.

- 금속 진공남땜이 필요한 금속부품 생산 분양

- Metallic parts manufacturers who need vacuum brazing and heat treating for steel.

- ASTM D2584에 따라 섬유강화합성물의 유리성분을 시험해야 하는 수질처리 분야

- Water treatment companies who test glass content in FRP (fiber reinforced polymer) products according to ASTM D2584.

- 질화갈륨 반도체 웨이퍼를 소둔하는 반도체 분야

- Semiconductor manufacturers who anneal Gallium nitride (GaN) semiconductor wafer.

- 다공세라믹튜브을 위한 양생과 소결방법을 연구하는 엔지니어링 분양

- Engineering companies who do curing and sintering solutions in porous ceramic tubes.

- 토양연소가 필요한 토목공학 분야

- Civil engineers who need soil combustion.

- 진공조건에서 실리카 웨이퍼를 소둔하는 연구 분야

- University labs who anneal Si wafer in vacuum condition.

- 탄소나노섬유(CNT) 전구의 열처리를 수행하는 화학연구분야

- Chemistry research departments who do the thermal treatments (stabilization in air and carbonization in argon) of carbon nanofiber precursors.

- 해상용 중유의 성분을 분석하는 해상장비제조분양

- Marine equipment manufacturers who analyze ash content in marine HFO (Heavy Fuel Oil).

- 화학증기증착기법(CVD) 을 이용한 그라핀기반재료를 생산하는 그라핀 연구, 개발 및 생산

- Graphene solution companies who produce graphene-based materials by CVD (Chemical Vapor Deposition) method. CVD furnace

- 폴리머, 옥사이드, 인산염, 황화물을 이용한 차세대 고체전지 개발분양

- Solid state battery manufacturer with polymer electrolyte, oxide electrolyte, sulfide electrolyte, phosphate electrolyte and etc.

구매하러 가기▼

https://smartstore.naver.com/vls0711/products/7617201136

1500℃ 튜브전기로 패키지 : 비전랩사이언스

Chemical Vapor Deposition (CVD, 화학기상증착) 공정용 전기로, annealing(소둔)용 전기로, Gas Flow package+이동형Frame + chiller + 진공펌프로 완변한 구성

smartstore.naver.com

문의 사항은 아래 연락처로 문의바랍니다.

전화문의 032-861-0282

팩스번호 032-861-0283

메일 vls0711@hanmail.net

'기초실험장비 > 전기로' 카테고리의 다른 글

| 1500℃ 튜브전기로 패키지(CVD,annealing) FU-PK-H4 (300mm Ø120) (0) | 2023.04.18 |

|---|---|

| 1200℃ 튜브전기로 패키지(CVD,annealing) FU-PK-G4-S (300mm Ø120) (0) | 2023.04.17 |

| 1200℃ 튜브전기로 패키지(CVD,annealing) FU-PK-G1-S (300mm Ø50) (0) | 2023.04.14 |

| 1800℃ 튜브 전기로(300mm) SH-FU-120TS (0) | 2023.04.14 |

| 1700℃ 튜브 전기로(300mm) SH-FU-100TS (0) | 2023.04.13 |